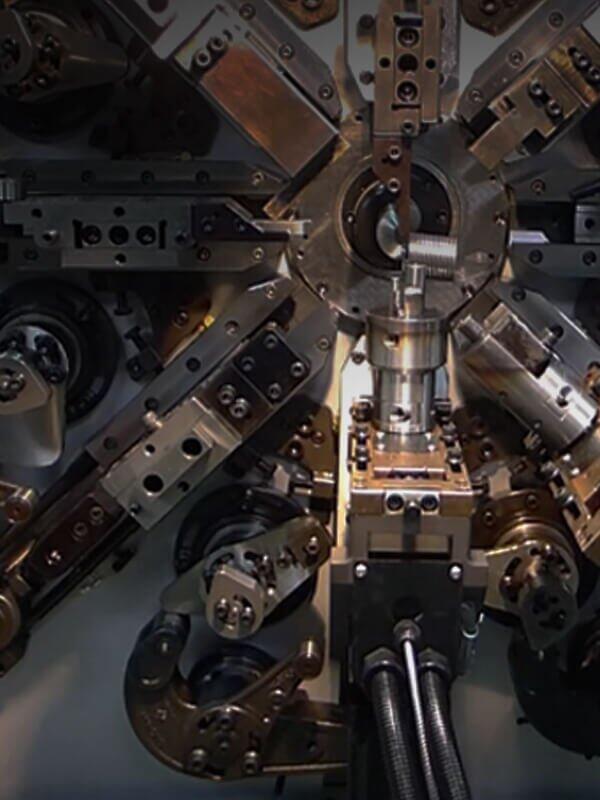

The grinding wheels are kept flat and parallel to each other. The springs are placed in a rotary carrier plate and passed between the wheels many times while the top wheel is fed down incrementally.

The rotation of the carrier plate and top wheel movement are controlled by servo motors. Downward cutting and grinding time is programmable, to avoid spring burnt out and achieve tighter tolerance of squareness and spring length.

Specification

Model No. | SEG-450-2S | SEG-660-2S | SEG-915-2S |

| Standard Axes | 2 | 2 | 2 |

| Grinding Wheel (pcs) | 2 | 2 | 2 |

| Grinding Wheel Diameter (mm) | 450 | 660 | 915 |

| Max. Spring Outer Diameter (mm) | 60 | 80 | 200 |

| Wire Diameter Range (mm) | 2.0~8.0 | 3.0~10.0 | 5.0~20.0 |

| Spring Length Range (mm) | 15~300 | 20~300 | 30~400 |

| Production Rate (pcs/min) | 8~60 | 6~45 | 2~75 |

| Plate Rotary Speed (rpm) | 1~40 | 0.5~30 | 0.5~30 |

| Grinding Stone Speed (rpm, 60Hz) | 1450 | 1000 | 730 |

| Spring Verticality (degree) | ≤ 1 (depends on the actual size) | ≤ 1 (depends on the actual size) | ≤ 1 (depends on the actual size) |

Power Supply | 220V, 3 phase, Transformer for 380/400/415/440V, 3 phase | 220V, 3 phase, Transformer for 380/400/415/440V, 3 phase | 220V, 3 phase, Transformer for 380/400/415/440V, 3 phase |

Machine Dimension (mm) | 1300x1750x2600 | 1600x2100x3000 | 1700x2500x3200 |

| Machine Weight (kg) | 2850 | 5100 | 6300 |

Video

* If you have any questions, please write to us. We will sincerely thank you *