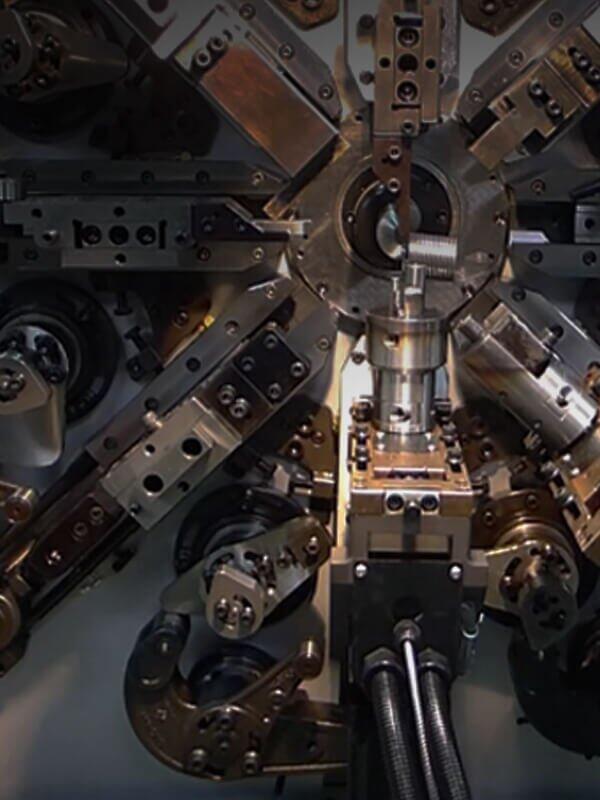

- All Electric-Servo Control

- Right-hand & Left-hand Bending in "One" process

- Auto Tooling Positioning Function

- PC-Based Control

3D tube profile can be shown immediately when editing YBC program to help users.

Under Auto mode, 3D tube graphic indicates current bending section by different color block.

3D Bending Process Simulation(Optional) directs bending process in advance to avoid unnecessary waste. - sBend Software

Fast Workpiece Parameter Acquisition:.dxf / .step files can be converted to Y.B.C data.

3D Workpiece Preview:Read-time 3D workpiece preview is acquired while Y.B.C data is being programmed.

3D Bending Simulation:Workpiece bending process can be previewed and verified in advance to prevent the waste.

Specification

| MODEL No. | TB-250LR | TB-300LR | TB-380LR | TB-380LRS | TB-500LRS | |

| Max Tube OD | Mild steel (mm) | Ø25.4 x 1.5T | Ø30 x 1.5 | Ø38 x 1.5T | Ø38 x 1.5T | Ø50.8 x 2.5T |

| Stainless (mm) | - | - | - | Ø32 x 1.5T | Ø38 x 2.0T | |

| Square pipe | - | - | - | □28 x 1.5T | □38 x 2.0T | |

Max Draw Bending Radius(mm) | 70 | 80 | 135 | 180 | 200 | |

Max. Effective Distance of Mandrel (mm) | 1500 mm | 1500 mm | 2000 mm | 2000 mm | 2500 | |

| Max Bending Angle | 180° | 180° | 180° | 190° | 190° | |

| Feeding (mm/sec) | 1100 | 1000 | 1500 | 1030 | 1000 | |

| Electric-Servo Speed | Rotation (degree/sec) | 750° | 750° | 750° | 450° | 200° |

| Bending (degree/sec) | 450° | 400° | 250° | 125° | 110° | |

| Feeding (mm) | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | |

| Electric-Servo Accuracy | Rotation (degree) | ±0.05 ° | ±0.05 ° | ±0.05 ° | ±0.05 ° | ±0.05 ° |

| Bending (degree) | ±0.05 ° | ±0.05 ° | ±0.05 ° | ±0.05 ° | ±0.05 ° | |

| Radius difference(mm) | 20 | 25 | 45 | 65 | 60 | |

| Power | 11 Kw | 13.2 Kw | 17.15 Kw | 26.7 Kw | 41.1 | |

| Machine dimension(mm) | 3300 x 1300 x 1300 | 3600 x 1730 x 1250 | 4300 x 1800 x 1500 | 4250 x 1200 x 1500 | 5200 x 1600 x 1900 | |

| Machine weight(kg) | 1,350 | 1,800 | 2,200 | 4,000 | 5,000 |

VIDEO

* If you have any questions, please write to us. We will sincerely thank you *