Introducing Simco Toolings

In recent years, the spring forming processing on the CNC spring machine has higher requirements for accuracy and specifications. Therefore, the durability and accuracy of tooling have been paid more attention to the issue.

Simco toolings can reduce indentations on the wire surface, making the springs less defective, more precise, and less likely to break. In addition, to increase the service life of the tooling, we also develop new material for tooling to make it more wear-resistant during production. For more information, contact us: simco@simcotw.com

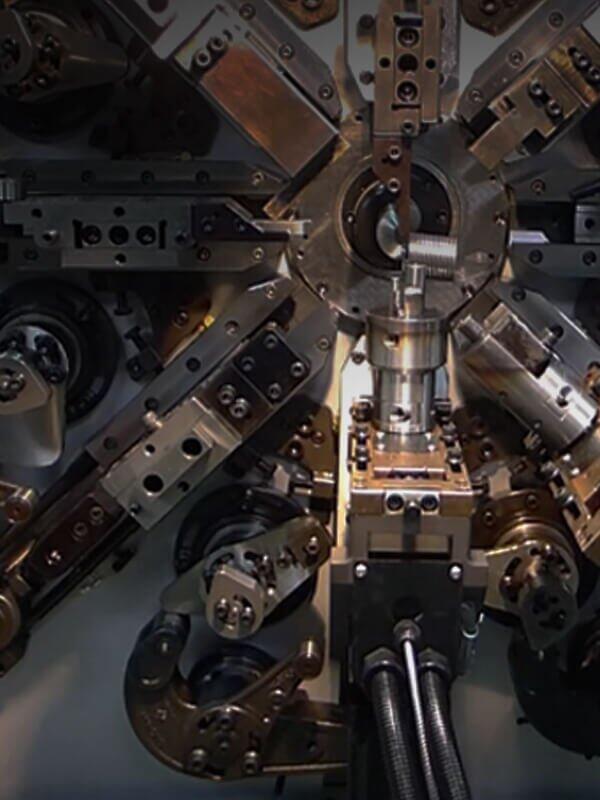

The toolings of the spring machine mainly include a feed roller, wire guide, arbor, coiling tool, cutter, pitch tool, etc.

1. Feed roller: provides the power to feed wire so the spring wire can accurately feed wire forward or backward.

2. Wire guide: make stable wire feeding at angles and straightening the wire.

3. Arbor: auxiliary cutting.

4. Coiling tool: controls the shape and outer diameter of the spring.

5. Cutter: cut the spring.

6.Pitch tool: control the function of the spring pitch.