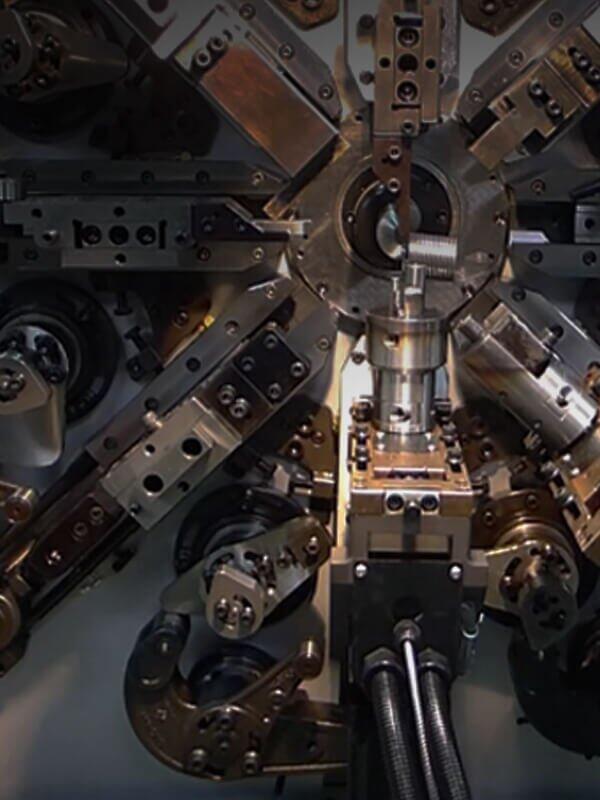

Why the EF Series Spring Machines Stand Out?

SIMCO EF series camless spring forming machines deliver a powerful combination of user-friendliness and unmatched performance compared to traditional cam machines. This makes them ideal for both experienced and new operators. The familiar operating mode ensures a smooth transition for existing cam machine users, while innovative servo motor technology and patented software unlock a new level of :

- Faster Setup and Changeovers: Servo motor control eliminates the need for physical cams, replaced by easily editable computer programs. This reduces setup times by over 50% compared to traditional machines.

- Increased Flexibility and Precision: Independent servo control of each axis allows for complex spring designs and tighter tolerances, exceeding the capabilities of cam machines.

- Simplified Maintenance: Fewer moving parts minimize wear and tear, leading to less downtime and lower maintenance costs.

- Easier Programming:Patented software features intuitive programming allowing the operator to look over the movements of all corresponding axes and optimize the settings.

- Unmatched Production Speeds: Quicker setups, precise control, and a simplified mechanical structure result in significantly faster production efficiency.

The EF series camless machines redefine the standards of spring forming with the following core features:

- Full-Servo Technology: Each axis is driven independently by a servo motor, allowing for free stroke settings and eliminating unnecessary movement. This results in enhanced forming capacity and improved working efficiency.

- Intuitive Programming: Spring programs are easily edited on the computer, achieving 100% production speed without complex cam arrangements.

- Advanced Industrial Computer System: SIMCO adopts a cutting-edge industrial computer system to ensure high synchronization and stable operation for maximum productivity.

2024-09-12