The Advantages of Pier Head Machines in Cold Pier and Shaping Processes

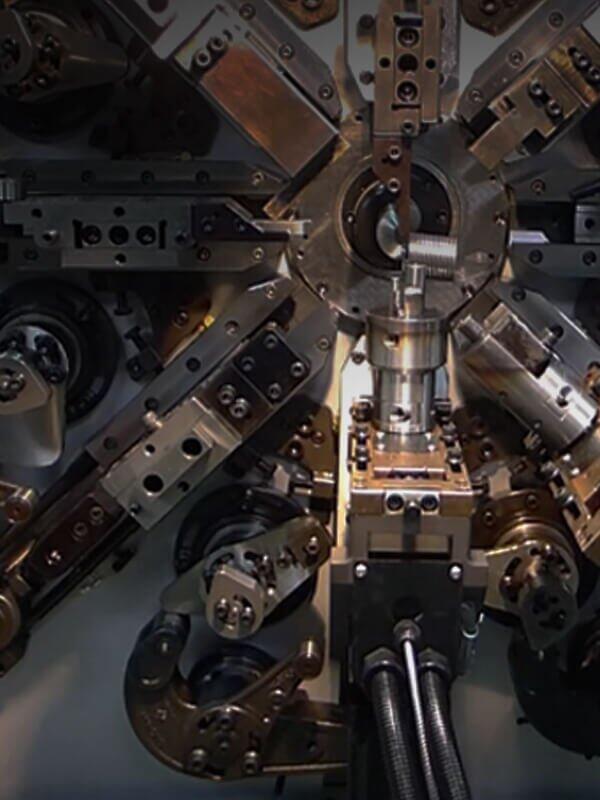

By equipping the pier head machine with our wire bending machine, you can achieve both the bending and pier head manufacturing processes on the same equipment, resulting in time and labor cost savings.

At the same time, this combination can also reduce material handling and transportation during the work process, and improve the continuity and efficiency of the production process.

There are six key advantages of pier head machines:

- Streamlined Processes with Computer Control: The machine integrates piercing and bending processes through computer control. With a single command, these machines can perform both tasks simultaneously, reducing production time and increasing efficiency.

- Enhanced Performance with High-Power Servo Motors: Pierhead machines utilize high-power servo motors from Japan, showcasing the perfect combination of intelligence and strength. This advanced technology enables one-step execution of cold pier and shaping operations, ensuring optimal precision and exceptional performance.

- Modular Design for Enhanced Performance: With high-speed cold heading capabilities, pier head machines deliver superior surface finish and consistent molding results, that enhance their overall performance.

- Robust Construction for Longevity: Pierhead machines are constructed with high-quality components, incorporating robust materials that ensure long-lasting performance. These durable and stable machines minimize downtime, maximize productivity, and guarantee long-term reliability.

- Versatility in Product Specifications: The machine can produce pier head products ranging from 5 to 13mm in diameter, with a focus on the frequently manufactured 7.5, 11, and 12mm variants. It is highly versatile, offering a wide range of working line diameters and accommodating multiple bending styles.

- Application in Various Wire Forming Products: Apart from its primary application in manufacturing automobile exhaust pipe hooks, the pier head machine's capabilities extend to the production of various wire-forming products after cold pier. Include wire brackets, wire clips, wire hooks, wire springs, wire rings, etc.

2023-07-13