Twist Cut Technology in Spring Manufacturing

Twist Cut Technology in Spring Manufacturing

Applications, Principles, and Selection Guidelines

Overview

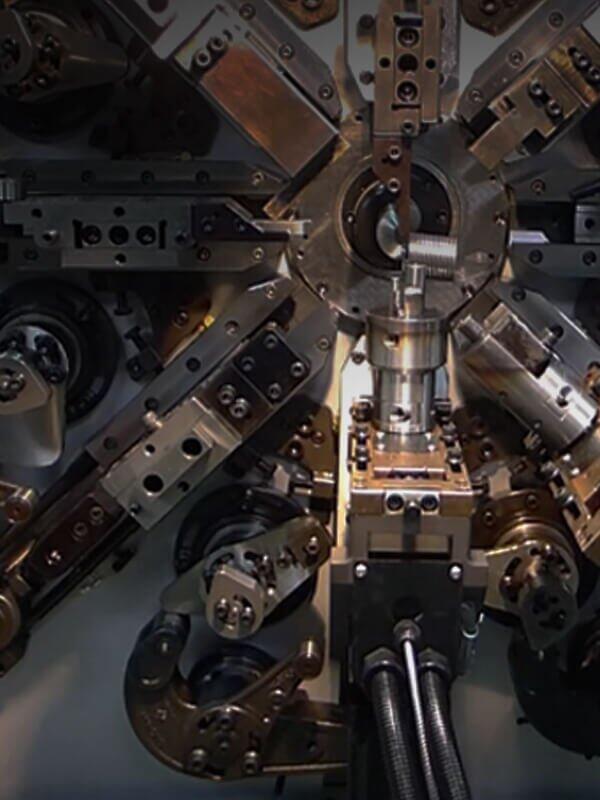

In spring manufacturing, the method of wire cutting plays a critical role in determining dimensional stability, end-face quality, and the effectiveness of subsequent forming processes. This is especially true when working with high-tensile, high-hardness materials such as oil-tempered wire. Traditional shearing methods often result in uneven cut surfaces, wire end deformation, or incomplete separation. As a result, twist cut technology has become one of the most common and effective cutting methods for medium- to high-hardness wire.

Basic Principle of Twist Cutting

Twist cutting involves applying both shear and torsional forces to the wire using two opposing moving blades, causing the wire to fracture rapidly at the cut point. Compared to traditional flat shearing, twist cutting leverages the brittle fracture mechanism of the material, resulting in a cleaner cut with reduced deformation. This method also lowers machine stress and helps extend tool life.

Two Types of Twist Cut and Application Conditions

✅ Single-Sided Twist Cut

In this method, the cutting force is applied from one side only. It features a simple structure and allows for high-speed production, making it suitable for large-scale manufacturing.

Application Conditions:

Spring index < 4 (tight coil spacing)

Materials with some brittleness or tolerance for end-face deformation (e.g., certain oil-tempered wires)

✅ Double-Sided Twist Cut

This method uses two blades on opposite sides that operate simultaneously or sequentially to apply shear and twist forces, creating a symmetrical fracture for better cut quality.

Application Conditions:

Spring index > 4 (looser coil spacing)

Suitable for high-tensile, high-hardness wires (e.g., SWP-B, music wire)

Ideal for thicker or harder wires when single-sided cutting is unstable