Benefits of Choosing an EtherCAT EF/SFX series Spring Forming Machine

Benefits of Choosing an EtherCAT EF/SFX series Spring Forming Machine:

Faster Speed: Unlike traditional pulse-wave servomotors, EtherCAT directly executes the stroke commands required for manufacturing without the need for real-time calculations during operation. This results in more accurate positioning and faster motor speeds.

Increased Production Capacity: The combination of faster speeds and a quicker tuning system leads to higher productivity and more precise products.

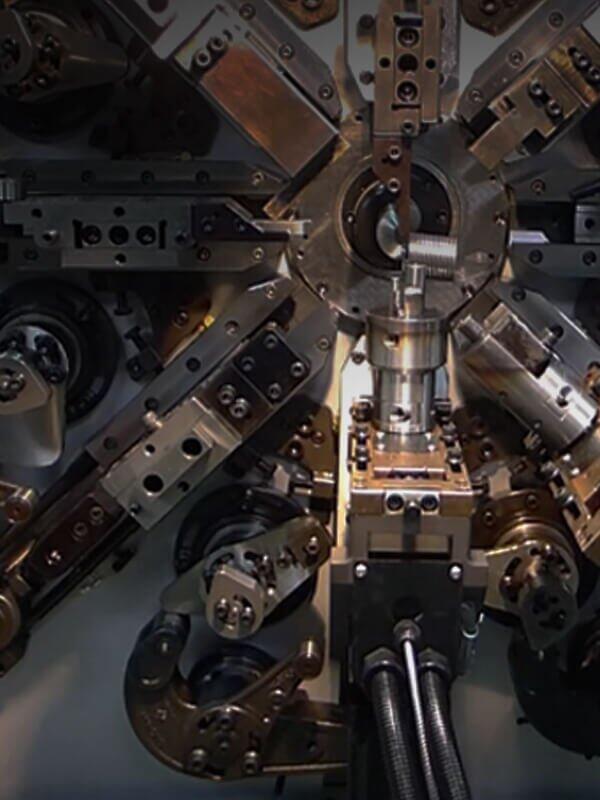

More Axes: Traditional controllers are limited in the number of axes they can handle. EtherCAT, using network cables for synchronous operation commands, can theoretically support up to 250 synchronized axes.

More Options: The EtherCAT Technology Group includes over 100,000 accessory and servomotor manufacturers worldwide. Users can choose from a variety of brands and models to meet specific needs, such as waterproof motors, high-speed, or economical models, enhancing machine efficiency and reducing costs.

Towards Industry 4.0: EtherCAT integrates most motor manufacturers' signal output formats, allowing equipment issues to be reported to the host and displayed on the user interface. This can also notify engineers remotely and facilitate software updates via the Internet.