What to Consider When Selecting a 16-32mm Large Wire Diameter Machine

When planning the production of large springs with diameters ranging from 16mm to 32mm, it is important to select the appropriate spring machine with care. These large wire-diameter springs present distinct challenges due to their size and weight. Here are key factors that require special attention:

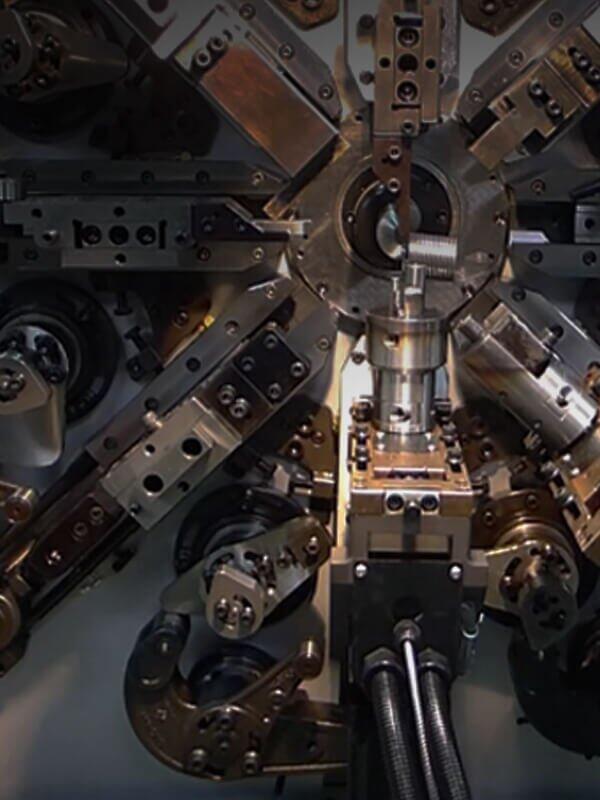

Load Capacity: Given the relatively large wire diameters of 16-32mm springs, they may demand greater force for wire processing and coiling. Ensure that the chosen spring machine possesses adequate load capacity to meet the machining demands of these sizable springs.

Precision and Control: Verify that the spring machine is equipped with a robust control system to guarantee that the springs' dimensions and performance align with the specified standards.

Wire and Material Handling: Manufacturing large springs might necessitate sturdier wire materials and potentially require special treatments such as heat treatment to ensure their performance.

Adjustability and Setup: The ability to adapt quickly and set up for various sizes and shapes of large springs is vital. Choose a machine capable of swift adjustments and setup to enhance production efficiency, such as those featuring a 3D graphic operation interface and on-screen parameter editing.

Maintenance Requirements: Large spring machines may demand more maintenance and upkeep; therefore, selecting an experienced and trustworthy manufacturer is paramount.

Safety: Ensure that the chosen spring machine complies with safety standards to secure the well-being of operators.

Cost: Finally, consider budget constraints, but avoid compromising on machine quality and performance.

In conclusion, the manufacture of large springs within the 16-32mm diameter range necessitates special attention to load capacity, precision, wire handling, production speed, adjustability, maintenance, and safety. Selecting the right spring machine ensures the production of large springs that meet quality standards and successful production.