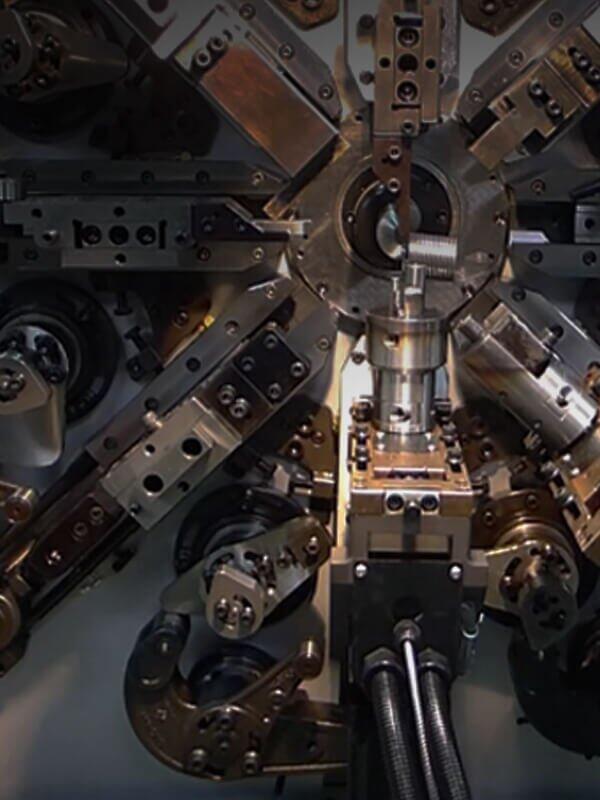

Method to maximize spring machine life

spring machines require long-term use and are also very high-value equipment. They require optimized maintenance during use to be able to function stably, and the application costs that need to be spent are relatively low

Routine maintenance: Focusing on cleaning, tightening, adjusting, and lubricating, routine spring machine maintenance should be performed as required before leaving the vehicle, at work, and after receiving the vehicle. This task is independently completed by the operator of the CNC spring machine.

Regular maintenance: According to the maintenance requirements of various mechanical equipment, after reaching the specified working time or the specified mileage, the corresponding regular maintenance must be carried out

Focuses on detection, adjustment, and elimination of hidden troubles. Diagnose and inspect the parts that affect the performance, and then complete the necessary replacement, adjustment and troubleshooting.