How to choose a tube bending machine?

The selection of a tube bending machine according to your bending operations can often become a complicated process. If you are considering the purchase of a tube bending machine, it’s better to choose the model according to parameters such as diameter, wall thickness, type of material, number of tool stacks, CLR angles and quality. Below are the recommended considerations:

Diameter

The diameter is the first factor to consider during the machine selection. The maximum diameter capacity distinguishes the feature of the machine. So, it’s important to define the range of tube diameters to be bent. Please make sure it is not too large as it will result in excessive and expensive tooling, as well as reduced productivity and increased energy consumption.

Wall thickness

The wall thickness is also critical. If the wall thickness of the tube is high, it’s needs a bigger force to bent and larger diameter capacity. Otherwise, if the wall thickness is thin, while there’s no need of a more bending force, it has to consider a risk of tearing or wrinkling at the bend location.

Type of material

The type of material is also essential for machine selection analysis. Materials such as low carbon steel, copper or aluminum are bent easily because they are ductile. If you use hard materials such as alloy steels or carbon steel, then would be more difficult to bend.

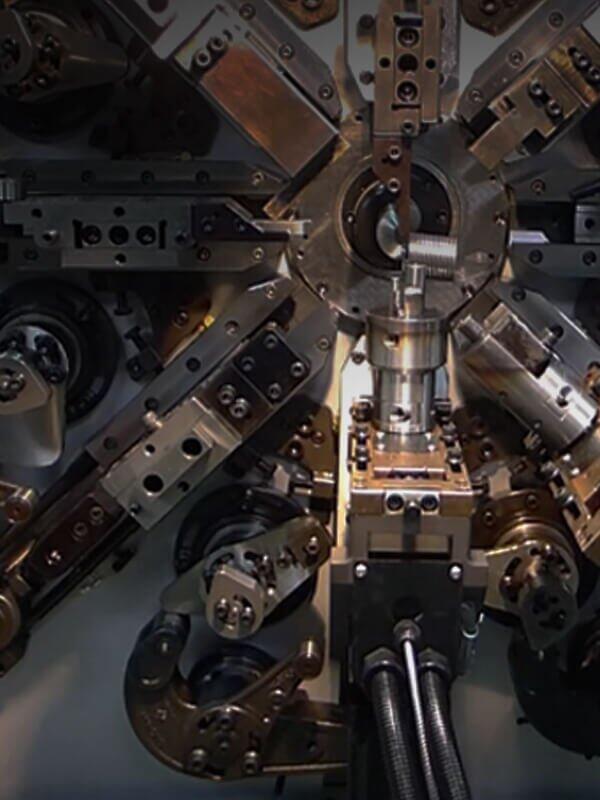

Number of tool stacks

The number of tool stacks is the capability to install multiple bending dies on the machine. When a tube bending machine has multiple dies, it allows a completion for a job with multiple radii. And also, allows the user to have freedom to bend different center line radius (CLR) and the distance between two bends.

Quality

Finally, you must consider the quality of tubes bending, such as the precision, repeatability, and aesthetic aspects. Components produced for the automotive, aerospace, industrial vehicle, and HVAC industries typically meet the machine’s standard. These are areas where curved parts are part of an assembly and where the overall geometry of the final tube is important.

In tubes for furniture or motorcycle exhausts, aesthetic aspects such as roundness of the bending areas and the absence of pinch marks and wrinkles are of great importance, since these parts are visible in the final product.

Conclusion

At the end, it is important to find that professional recommendations during your machine selection, because a tube bending machine would be a one-time investment, and would be important to increase the manufacturing reputation of your company. Also is necessary to analyze costs in production, maintenance, and production to make a correct decision in the purchase of your tube bending machine. Therefore, it is required to take all the above parameters into consideration.