SIMCO's new EP tooling solution enhances production stability for customers

By providing a protective barrier against wear, friction, and chemical reactions, Tooling coatings have revolutionized machining operations in various industries, and become an indispensable part of modern machining processes. As they extend tool life from 100 thousand to 800 thousand times, significantly reduce downtime, and improve productivity.

These coatings offer benefits such as increased tool life, improved cutting speeds, enhanced surface finish, reduced cutting forces, heat resistance, chemical resistance, and enhanced tool versatility.

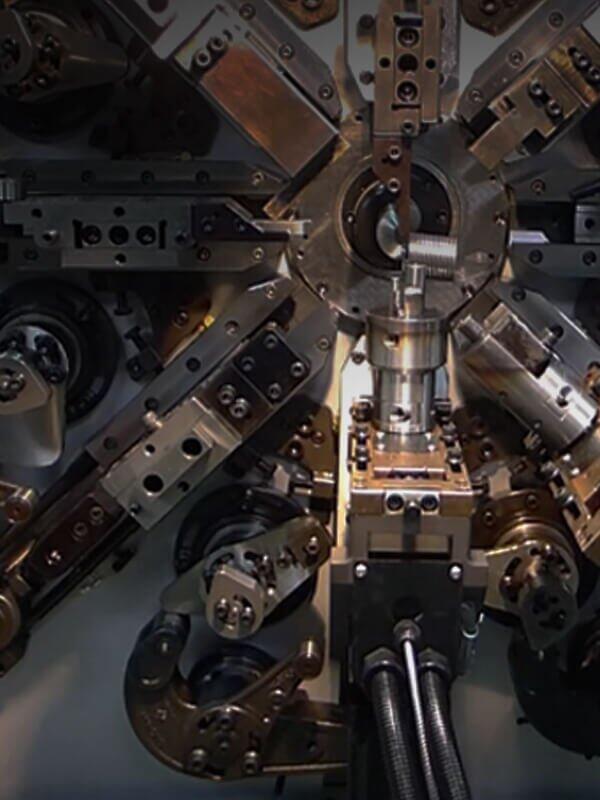

SIMCO develops special tooling called EP Tooling. It involves depositing a thin film onto the tool's surface through a vacuum process, creating a highly adherent and wear-resistant coating that enhances durability and performance.

The advantages of our EP tooling for spring machines are as follows:

Enhanced Wear Resistance: EP Tooling is highly resistant to abrasive wear, reduces wear, and prolongs the life of the knives. It makes it crucial for spring machine knives that have continuous contact with the workpiece.

Reduced Friction and Heat Generation: EP tooling has a low coefficient of friction, minimizing frictional forces between the tool and workpiece. This reduces heat generation, prevents chip accumulation, improves chip evacuation, and prevents premature tool failure.

Improved Surface Finish: Spring machine tools with EP tooling deliver precise and smooth cuts, ensuring exceptional surface finishes. This is vital for spring manufacturing, which requires high precision and consistency.

Chemical Resistance: EP tooling offers excellent resistance to chemicals and coolants used in machining operations, protecting the tools from corrosion and maintaining their performance in challenging environments. Our knives can be rust-proof for at least 10-20 years because of special coatings.

Versatility and Cost-effectiveness: EP Tooling can be customized for specific applications and materials, making them highly versatile. The extended tooling life reduces tooling change frequency, minimizing downtime and cost for customers.

By integrating EP Tooling in the manufacturing of knives, SIMCO provides top-of-the-line tools for spring machine applications. Embracing EP Tooling ensures that SIMCO remains at the forefront of the industry, offering cutting-edge solutions for the evolving demands of spring manufacturing.