What machine should be used for making complex springs?

What machine should be used for making complex springs?

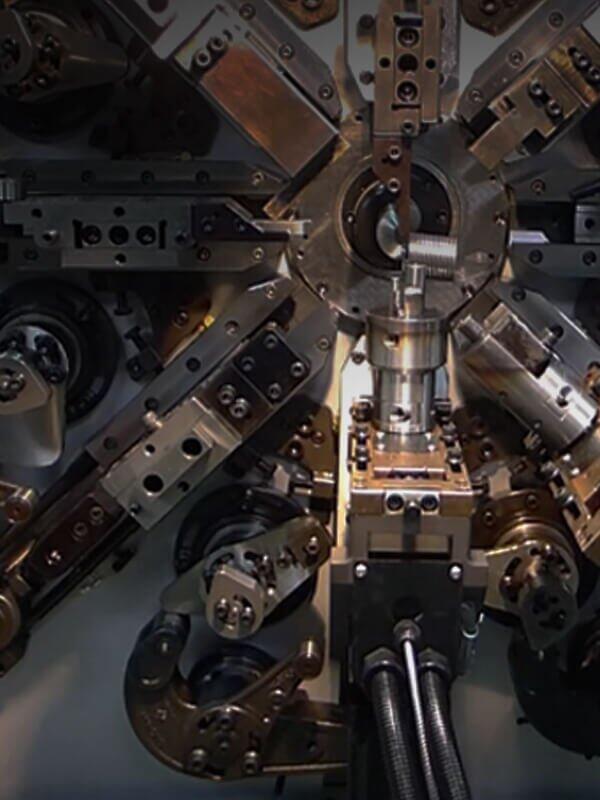

In a multi-axis spring-forming machine, the term "axis" refers to the supporting mechanism that connects various components. These mechanisms are driven by servomotors to execute production operations. The number of axes directly influences the precision, forming results, and processing efficiency of the machine.

To produce complex springs and get free of the limitation of a single plane, you can consider spring-forming machines instead of spring coilers.

The earliest 3-axis cam spring forming machine features eight cams on its working panel, all controlled by a single servomotor. However, each bender is confined to shaping angles in a single plane. This limits the forming capabilities and requires intricate machine tuning. Skilled technicians are needed to adjust the cam phase accurately.

Later, it evolved to add a wire-rotating axis to the traditional three-axis cam spring-forming machine. This innovation frees each bender from the constraints of a single plane, enabling 3D angle formations. This enhances its forming capabilities, allowing for more intricate shapes.

SIMCO's entire machine development has evolved from cam machines to camlessmachines, and each evolution has continuously improved efficiency, performance, and flexibility.

For springs with specific characteristics below, the multi-axis EF series and SFX series are particularly recommended:

- Springs requiring tight tolerances: Independent servomotors drive each axis, allowing individual benders to move with varying strokes and speeds according to the program. This reduces mechanical tolerance driven by gears, resulting in more accurate final products.

- Complexly-shaped springs: Some springs necessitate multiple angles for completion. Additional axes offer greater flexibility and power for shaping.

SIMCO EF series and SFX series multi-axis formers excel at intricate forming. Their unique timeline function and flash mode streamline and integrate unnecessary actions, boosting production capacity by 2 to 3 times compared to traditional cam machines when crafting specialized springs.